The main objectives of United Productions Atom LLC in providing services

-

- Safe and efficient performance of complex routine maintenance, in particular engineering, installation, repair, reconstruction and modernization of NPP equipment.

- Supply of equipment and spare parts to nuclear power plants.

- Installation, repair, reconstruction and modernization of NPP equipment.

- Comprehensive engineering and technical support and organization of repair maintenance of NPP equipment.

- Organization of planning and execution of repairs and maintenance of NPP equipment in accordance with the requirements, rules and standards in the field of nuclear energy use, as well as the conditions of the obtained permits.

- Maintenance of repair work, operational control and analysis of repairs and equipment maintenance.

- Engineering, service maintenance and supply of equipment, as well as spare parts for NPP pumps in accordance with the requirements of norms, rules, standards and permits in the field of nuclear energy use.

- Development and approval of repair documentation for equipment supplied to NPPs by both United Productions Atom LLC and other manufacturers.

Installation supervision

- Propositions to improve the quality of repair work for the main pumping equipment of VVER-1000 and VVER-440 units with exception of technical and technological risks.

- The participation of an experienced chief engineer during the assembly of the detachable part of the MCP directly at the NPP during its repair.

The participation of an experienced chief enginee is necessary due to the specific design features and nuances of the seal and its assembly. The mechanical seal unit of the MCP-195M pump shaft is designed to prevent water leaks in the primary circuit and consists of the following main parts: a housing with a built-in cooler; bushings; separating, first, second and end stages. In order to reliably prevent water leaks in the primary circuit from the pump through the internal channels of the casing, cooled blocking water with a pressure exceeding the pressure at the discharge of the MCP by 5 … 8 kgf / cm² is supplied. In this case, part of the blocking water (up to 0.05 m³/h) can enter the primary circuit through the separating stage, and part is throttled in the external throttles, while cooling the main stages.

During normal operation of the seal, the pressure between the main face stages is distributed almost equally due to the external bypass throttles.

In the event of an emergency failure of one of the face stages, the remaining stage will throttle the total pressure drop. In this case, the pump must be stopped by the control room operator.

While assembling a mechanical seal after repair, there are situations arise periodically when the pressure throttling in the sealing stages differs significantly from the specified standards. It should be noted that the pressure distribution shall be monitored after the mechanical seal unit is installed in the MCP.

The analysis revealed several factors that can lead to such situations:

Clogging of throttles or a change in their flow capacity (erosion of throttling holes), damage to rubber O-rings, uneven wear of springs and pins of axially moving elements, etc. Thus, even a step-by-step control of the installation of every elements of the seal unit during its assembly cannot be an absolute guarantee of its operability after installation in the pump. In order to eliminate this problem, a test bench can be used, which makes it possible to determine (without installation directly into the MCP) both the pressure drop between the stages (static tests) and the actual values of the leakage through the separating stage in dynamics.

Test bench for MCP seals

To prevent the occurrence of such situations, UP-ATOM offers services for the development, manufacture, supply and commissioning of a bench for crimping the packing gasket and checking (testing) the operability of MCP seals on site of the NPP unit repair base directly in the “dirty zone”. If necessary we can also train station personnel in qualified and safe work at the bench. This will allow to completely eliminate possible risks associated with the defect occurances during the assembly of the seals (to detect and promptly eliminate all defects even before installing the seal in the MCP), which generally are detected after the block is warmed up and the pump is fully operational at “hot” operating mode.

The complex thst bench for MCP-195M seals is designed to check the stability of their operation by determining the compliance of the main characteristics with the requirements of technical documentation.

Manufacturing and delivery of a device for removing the stuck-on studs of the main MCP connector at the NPP unit while repairing.

The need for this device (portable machine tool) is caused by specific features (the pins of the main MCP connector “stick” to the base metal of the pump casing during long-term operation at variable temperature conditions).

Our company can carry out the development, manufacture and supply of a workable and reliable device (a portable machine installed on the MCP housing connector) for removing stuck-on pins of the main connector, restoring (preserving) the old M100 thread in the body or boring and cutting a new M110 thread for replacing the pins. This device will eliminate the problems of inspecting the threaded parts of the studs and MCP housings during repairs.

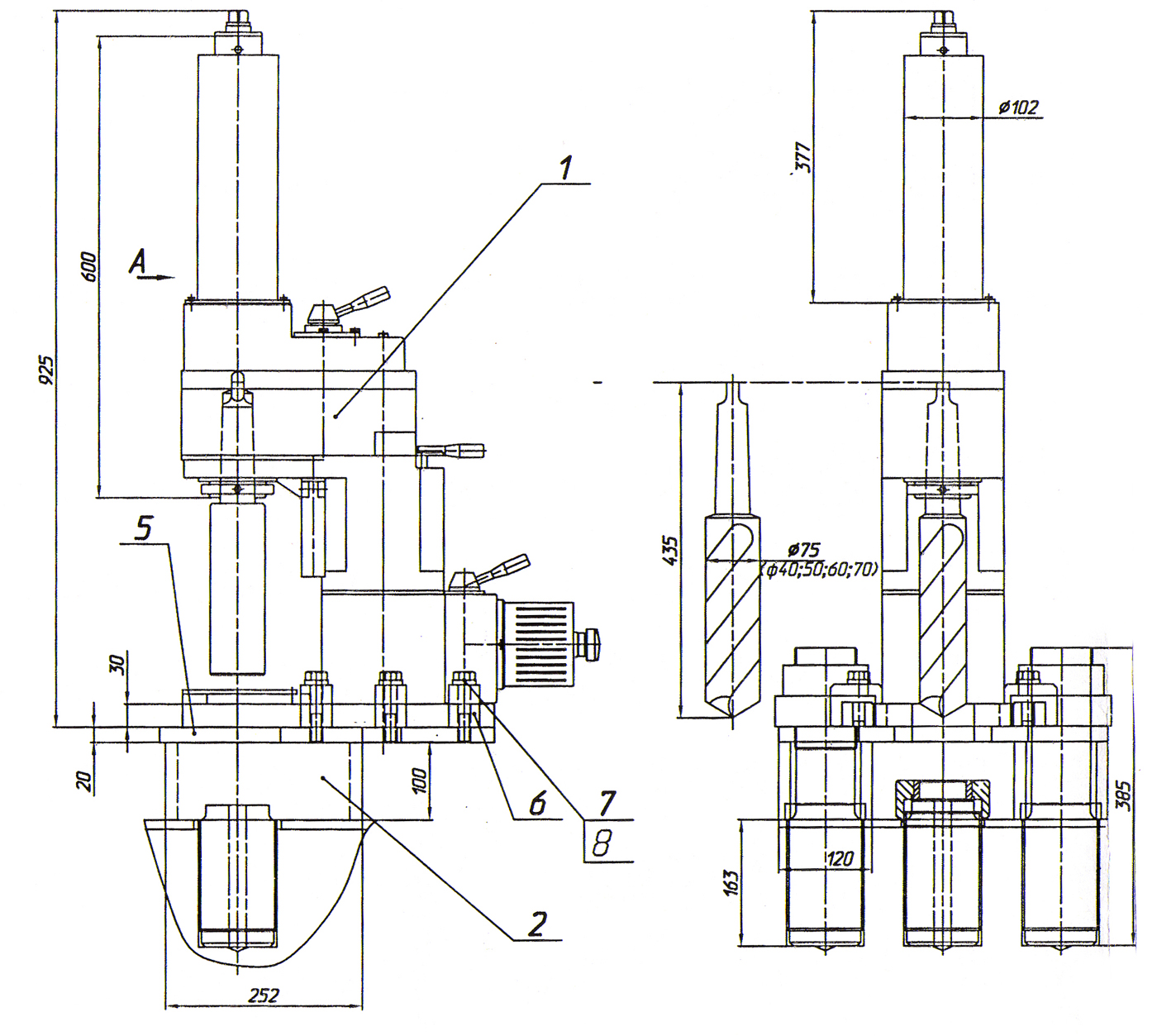

The main power component of the device is the drilling and boring head А.1-11084.100.00. The head is an L-shaped structure, consisting of: pneumatic drive, two-stage planetary gearbox, transmission, spindle assembly, threading spindle assembly, friction clutch, and a set of tools.

English

English Russiche

Russiche